Advantages of Eyeleting Machine

We all know how tedious and time-consuming it can be to hand-punch eyelets into the fabric. It's a laborious process that requires precision, but with the right tools, you can make the job a lot easier - and faster.

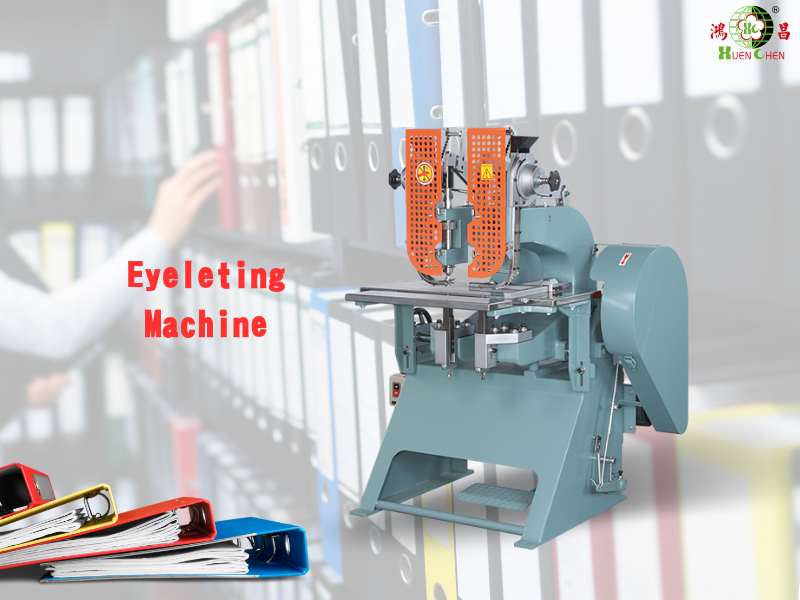

That's where an eyeleting machine comes in. An eyeleting machine is designed to quickly punch holes into fabric and securely attach metal grommets or rivets in one easy step, making them ideal for large projects such as upholstery, banners, tents, and other fabrics requiring reinforced rings or hooks.

But what are some of the advantages of using an eyeleting machine? Let's take a closer look at why these machines are so popular among craftspeople everywhere.

Advantages of Using an Eyeleting Machine

Like any other tool, an eyeleting machine offers a variety of benefits that make it a great choice for your fabric projects. Here are some of the advantages you can expect when using an eyeleting machine:

Increased Efficiency

Using an eyeleting machine can help businesses increase productivity and reduce production costs. By automating the eyeleting process, businesses can speed up production rates and produce more items in less time. Additionally, this tool eliminates the need for manual labor, saving businesses money on labor costs.

Improved Quality and Accuracy

Manually sewing eyelets can be a time-consuming and challenging task, often resulting in uneven spacing and inconsistent sizes. With an eyeleting machine, you can achieve professional-looking results every time. The machine produces evenly-spaced holes of the same size as the eyelets and can also set them in place with a neat, finished look.

Time Savings

An eyeleting machine is a powerful tool that can save you time and money by significantly reducing the manual labor associated with setting eyelets. With this tool, you can quickly and easily attach eyelets to fabric, significantly reducing production times. Plus, eyeleting machines are user-friendly, making it easy for businesses to train employees to operate them effectively.

Cost Savings

Eyeleting machines can help businesses save money in the long run. By eliminating the need for manual labor, companies don't have to spend money on labor costs. In addition, an eyeleting machine requires minimal maintenance, resulting in low maintenance costs over time.

And it's a fact that when you produce more in less time, you save money. So, if you're looking to speed up your production and reduce costs, an eyeleting machine is a great choice.

Reliability and Quality

The presence of detectors in the machine ensures proper positioning of the eyelet and washer, reducing the risk of damaging the work. This results in increased reliability and durability of the finished product. Additionally, eyeleting machines are designed to be highly durable and reliable tools that can withstand long hours of use without fail.

Warnings and Maintenance

The machine has alert systems that indicate when eyelets and washers must be changed, as well as when preventive maintenance is necessary. This feature helps you maintain the machine in good condition and avoid any risks of damage or malfunction.

Safety

Multipress eyelet machines are designed with safety in mind. With built-in protection devices and a CE marking, you can rest assured that the machine is not only reliable but also compliant with all applicable safety regulations. This ensures no unnecessary risks when using this powerful device to complete your task quickly and efficiently.

Versatile

Multipress provides versatility to adjust the setting according to your requirements and the materials used. You have a choice of employing a pre-cutting mode or simply using eyelets for your setup. This allows you to configure the machine in a way that suits your project best.

How to Choose the Right Eyeleting Machine for Your Needs

Assess Your Needs

When it comes to fabric projects, an eyeleting machine can be an indispensable tool. With a wide range of models available in the market, it can be challenging to select the right one that fits your specific needs. However, with a little research and consideration of your requirements, you can choose the perfect machine that will take your projects to the next level.

Consider the Type of Material and Size of Eyelets

The first step in choosing the right eyeleting machine is to assess your needs. Consider the type of material you will be working with and the size of the eyelets you will be setting. This information will help you select a machine that has the appropriate capabilities for your projects. For example, if you will be working with thicker materials, you may need a machine that can handle more pressure to set the eyelets securely.

Speed and Efficiency

If you have a high volume of projects, you will want a machine that can quickly and accurately set the eyelets, saving you time and reducing the risk of mistakes. Advanced models, such as Multipress, have high speed and efficiency, making them an ideal choice for high-volume projects.

Maintenance and Ease of Use

It's essential to take into account the machine's maintenance and ease of use. Look for machines with warning indicators that remind you when it is time to replace the eyelets and washers and when preventive maintenance is required. In addition, a machine with a user-friendly interface and easy-to-follow instructions will make your work much easier.

Must Look For Safety

Safety is another crucial factor. Ensure that the machine has protection devices for the eyelet setting process and has the CE marking, which confirms compliance with safety regulations. This will help you avoid unnecessary risks and ensure the safety of your projects.

Adaptability

Finally, consider the adaptability of the machine. A machine that can perform different modes of eyelet setting, such as pre-cutting mode or just eyelets, will allow you to work with a variety of materials and meet your unique needs. The Multipress model, for instance, offers excellent adaptability, making it an ideal choice for versatile projects.

Conclusion

With so many advantages, an eyeleting machine can make your projects easier and more efficient. By following the tips above, you can choose the right one for your needs. For projects requiring versatility and high speed, the Multipress model is an excellent choice. With its advanced features and safety regulations, it's the perfect tool to take your projects to the next level.